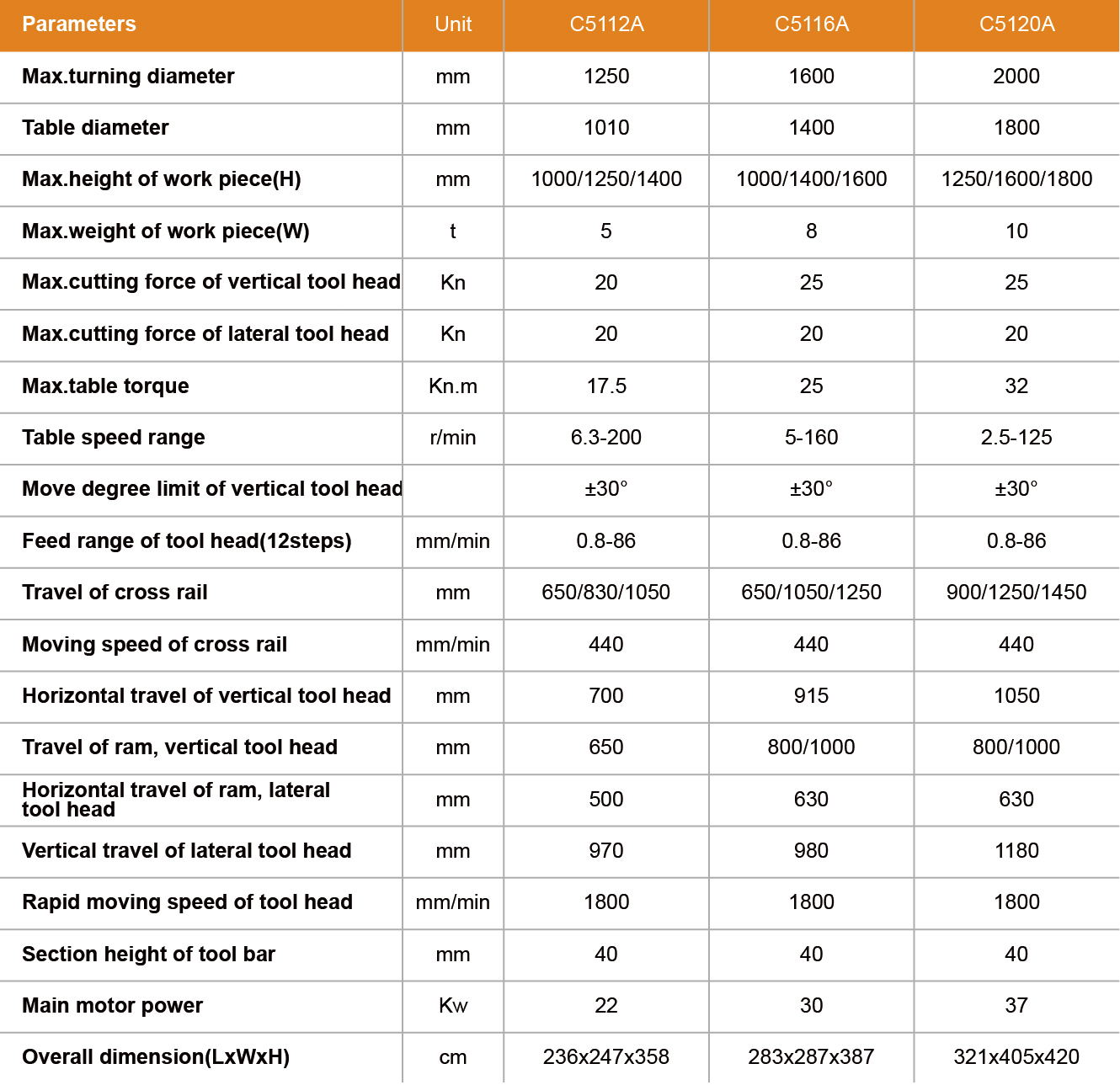

ORDINARY CAR C51 SERIES

Vertical lathe process range is very wide, can be turning inside and outside the cylinder, cone surface, the forming surface of revolution and circular groove, turning end face and metric, inch, module, thread diameter section, drilling, reaming, reaming can also away L, tapping screw, screw thread and knurling, etc.As you can see, to complete a variety of machining operations, lathe must meet the following movement: the rotation of the workpiece movement - the main movement;Moves in a straight cutting tool - feed movement.In ordinary cutting, the workpiece rotation movement and the movement of the tool, as two independent of each other simple movement, and in the thread machining, because of the workpiece rotation and cutting tools must be kept in strict movement relation between mobile, so they are combined into a composite forming - spiral trajectory motion, this is a link chain, traditionally called thread feed movement transmission chain.

The characteristics of the vertical lathe is: low degree of automation, auxiliary movements performed by the operator, auxiliary time more, low productivity, suitable for single piece and small batch production and overhaul mold workshop.Vertical lathe spindle box, tool post, tailstock, feed box, slip board box, lathe bed of six parts.

Single column vertical lathe: 1. This series machine is suitable for the industries of machinery processing, can be used for the outer cylinder. Tapered surface. End. Grooving. Cut, etc. Of coarse fine turning processing.2. The vertical lathe workbench with zinc alloy wear-resistant guide plate, and between the guide rail pass into the pressure oil, spindle radial NN30 type double row cylindrical roller bearings with high precision rotary precision bearing capacity is big.3. Vertical lathe workbench speed can choose 16 speed adjustment, and can choose frequency conversion stepless speed regulation.Tool rest can choose 12 speed-control feed and optional frequency conversion stepless speed regulation of feed.4. Set up car castings after strict artificial aging and vibration aging, to ensure the machine tool rigidity and stability.5. The use of advanced super audio quenching process, make the machine service life is longer.

Ordinary vertical lathe C51 series of lathe bed structure: the vertical lathe bed is the foundation of the whole machine tool bearing parts, used for important components, such as spindle box, guide rail is placed at the same time bear shear effect.Basic requirements for nc machine tool bed are: enough static stiffness, good dynamic characteristics, smaller thermal alteration, easy to install.Good dynamic characteristics need machine to have enough dynamic stiffness and damping, right have higher inherent frequency, away from the excitation frequency, and avoid resonance because of thin wall vibration and noise, but should also have good thermal stability.

(1) the layout of the structural layout is reasonable can effectively reduce the component by bending moment and torque, enhance the stiffness.Spindle box single hanging in the column profile, spindle box of gravity will make the pillar to the larger bending moment and torque load, easy to bend and torsion deformation, which directly affect the machining accuracy.The center of the spindle box of the symmetry center in column surface, spindle box of bending moment and torque is small, weight does not generally guide pillar deformation.

(2) the lathe bed section of the lathe bed has the very high bending and torsional rigidity.

(3) the floor layout reasonable decorate floor structure can achieve high stiffness weight ratio, natural frequency away from shock

The frequency.

(4) the sand box sealing structure of lathe bed sand sealing structure is to use floor isolation into a closed enclosure structure, will remain in the casting mold core is not

In addition, good vibration absorbing performance using sand and can improve the damping ratio of structures, there are obvious vibration suppression can be improved

The static stiffness of the body structure.

Copyright © Jiangsu Hoston Machine Tools Co., Ltd. (Hongkong Hoston Group CO., LIMITED)All Rights Reserved | Sitemap Technical Support: