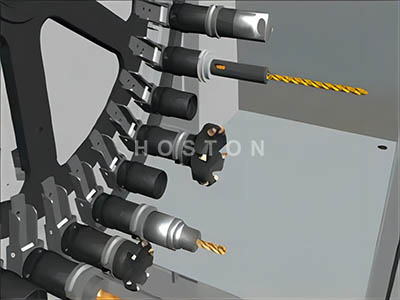

What is the reason for the failure of the tool changing manipulator? How to solve it?

There are generally three types of manipulator failures:

1. The tool clamp is not tight. It may be that the spring pressure of the clamping claw is too small or the nut behind the spring is loose, or the tool is overweight, and the clamping lock does not work, etc.

2. The tool cannot be loosened after being clamped. The reason may be that the spring of the loose lock is pressed too tightly, and the claws cannot be retracted. The nut should be loosened so that the maximum load does not exceed the rated value.

3. The tool is dropped when the tool is changed, or the spindle box does not return to the tool change point or the tool change point drifts when the tool is changed. It may be because the manipulator started to pull the knife when it was not in place when grabbing the knife, which would cause the knife to drop. At this point, the headstock should be moved again to return to the tool change point to reset the tool change point.

Copyright © Jiangsu Hoston Machine Tools Co., Ltd. (Hongkong Hoston Group CO., LIMITED)All Rights Reserved | Sitemap Technical Support: