6. Solenoid valve

Automation factory switch

Solenoid valves are electromagnetically controlled industrial equipment. They are the basic components for controlling fluids. They are actuators and are not limited to hydraulic and pneumatic.

Used in industrial control systems to adjust the direction, flow, speed and other parameters of the media.

The solenoid valve can be used with different circuits to achieve the desired control, while the precision and flexibility of the control can be guaranteed.

There are many types of solenoid valves, and different solenoid valves function in different positions of the control system.

The most commonly used are check valves, safety valves, directional control valves, speed control valves etc.

7. Industrial camera

Automated factory eyes

Industrial cameras are a key component in machine vision systems. The most essential function is to convert optical signals into ordered electrical signals from the AFT-808 compact HD industrial camera.

The image system performs various operations on these signals to extract features of the target, and then controls the action of the device on the spot according to the result of the discrimination.

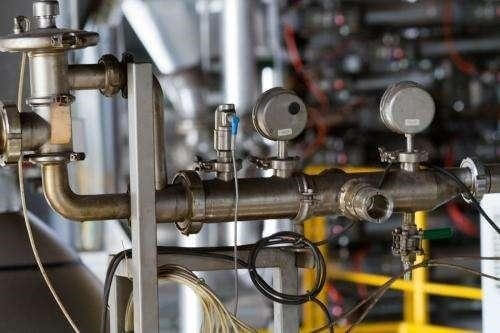

8. Instrumentation

Automation plant’s conditioning system

Instrumentation is an instrument or device used to detect, measure, observe, and calculate various physical quantities, material compositions, physical parameters, etc.

Vacuum leak detectors, pressure gauges, length gauges, microscopes, multipliers, etc. are all instruments.

Various instruments and meters need to be applied in an automated factory.

For example, measuring the pressure, liquid level, flow rate, temperature and other parameters required for some control processes requires relevant instrumentation.

9.Automation software

The heart of an automated factory

As the industrial control system is connected to the traditional IT management system and the Internet, the general control software, general hardware and general protocols are increasingly used internally.

More common is the SCADA automation software.

The SCADA automation system (supervisory control and data acquisition) is what we call the data acquisition and monitoring system.

It is mainly a system that is supported by computer technology and performs automatic control of scheduling of various production processes.

SCADA automation software can automatically and accurately monitor production for a long time without being supervised, and obtain effective information data from it, providing a powerful evaluation reference for regulatory administrators.

10.Control cabinet

Automation plant’s central system

The control cabinet also includes many types, including:

.Electrical control cabinet

.Frequency control cabinet

.Low voltage control cabinet

.High pressure control cabinet

.Pump control cabinet

.Power control cabinet

.Explosion-proof control cabinet

.Elevator control cabinet

.PLC control cabinet

.Fire control cabinet

.Brick machine control cabinet

Control cabinets for electrical, variable frequency, power, water pump, etc. are involved in the automation plant.

Different control cabinets are selected according to different needs to achieve different control functions.

Copyright © Jiangsu Hoston Machine Tools Co., Ltd. (Hongkong Hoston Group CO., LIMITED)All Rights Reserved | Sitemap Technical Support: