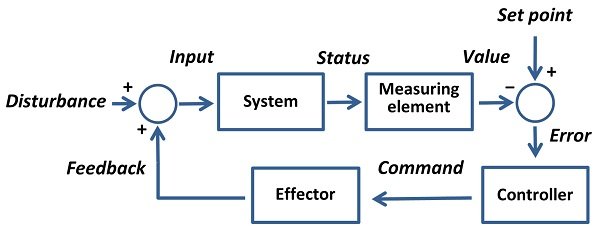

The point control system is a position servo system.

It is a comprehensive control system that uses electronic technology, computer technology, automatic control and detection to make the controlled terminal reach the destination according to the given trajectory and speed.

The point control system generally includes a final mechanical actuator, a mechanical transmission mechanism, a power component, a controller, a position measuring device, etc.

The mechanical actuator is the action component that finally completes the functional requirements, such as the arm of the welding robot and the work table of the CNC machining machine.

In a broad sense, the actuator also includes moving support members such as guide rails, which also play a key role in positioning accuracy.

Point control has a wide range of applications in the field of mechatronics and the robotics industry.

At present, the tracking of part contours by CNC machine tools in the mechanical manufacturing industry, the fingertip trajectory control of industrial robots and the path tracking of walking robots are typical applications of point control systems.

Significance

Point control has a wide range of applications in the field of mechatronics and the robotics industry.

At present, the tracking of part contours by CNC machine tools in the mechanical manufacturing industry, the fingertip trajectory control of industrial robots and the path tracking of walking robots are typical applications of point control systems.

In recent years, with the development of science and technology, wafer processing equipment, the use of medical surgical robots, point control is its key technology, with innovative significance and very high practical value.

Point control system classification

The point control system is actually a position servo system.

Their basic structure and composition are basically the same, but the focus is different.

Their control complexity also has its own merits.

Generally speaking, the position servo system emphasizes stability, fast and no overshoot, small following error, wide speed range, high precision and high dynamic characteristics.

The point control system requires high positioning accuracy and positioning time.

For the point control system with trajectory requirements, almost all requirements of the position servo system are included.

The point control system is divided by feedback method and can be divided into:

. Closed loop system

. Semi-closed loop system

. Open loop system

Closed-loop control system of point control system

The closed-loop control system mounts the position detector on the final output shaft (or platform), so that the most accurate position information of the terminal can be obtained, and high-precision positioning can be achieved by closed-loop feedback.

If the mechanical transmission system has a high stiffness or a very small inertia, the natural frequency of the mechanical transmission system is much larger than the natural frequency of the motor system.

Then the frequency characteristic of the positioning system depends on the frequency characteristics of the speed loop, and the positioning system can be reduced to a second-order system.

For different characteristics and requirements of the positioning system, different situations should be simplified to reduce the complexity of the design.

In theory, the thinking method of the closed-loop system is the most ideal.

It not only eliminates the error of the electrical control system, but also eliminates various errors in the drive chain.

But this control idea is difficult to implement.

Mainly due to the electrical and mechanical disasters, there are many non-linear factors, such as the transmission gap, the nonlinearity of the friction characteristics, the transmission stiffness is not fixed, etc., causing the system to have resonance, creep and other unstable factors and other unknown factors.

In addition, load changes will also affect the friction characteristics of the system, mechanical inertia, etc., making it difficult to set the system.

Semi-closed loop control system of point control system

The semi-closed loop system is characterized in that the mechanical transmission system is not included in the ring, and its position measuring element is generally mounted with the end shaft of the motor.

Semi-closed loop systems are widely used. Generally speaking, closed loop systems often refer to such systems.

The feedback link does not include the mechanical transmission system, which avoids the introduction of many nonlinear factors and the system is easy to implement.

However, it can not compensate the transmission error of the external transmission system, and can not compensate for the gap error and other factors, so the control accuracy is also reduced accordingly.

In order to improve the control accuracy, certain compensation measures can also be taken, such as calculating the transmission error and the reverse gap in advance, and adding these errors to the control system to improve the accuracy.

However, the transmission error, the reverse clearance, etc. may vary with friction, mounting position, and stiffness.

In addition, temperature, lubrication, load and other changes will also change, so the ability to improve accuracy is limited.

Open loop control system of point control system

This control system is a relatively primitive system.

Because of its simple control method, low system cost and mature technology, the citation is also very extensive.

The feature of this system is that there is no position detection device, and the accuracy is achieved by the controller, performing the performance of the motor and the transmission system.

The most typical system is a position servo system using a stepper motor.

Such systems often adopt a one-way operation mode to overcome the influence of the reverse gap when the positioning requirements are relatively high.

Or various gear-driven anti-backlash devices can be used in case of reversal, but they have certain limitations, such as increasing structural complexity.

It is difficult to adjust itself, and most of the anti-backlash devices cannot eliminate the gap backlash. In addition, friction is added to accelerate the adverse effects such as wear.

For some loads, the inertia is large and there is a large acceleration and deceleration, the stiffness of the transmission chain will have a great impact on the positioning accuracy.

Considering the stiffness and damping of the transmission chain, the transmission chain is generally a second or similar second-order oscillation.

For such a transmission chain, whether it is the impact of the motor starting or stopping or the constant value of the motor (step function) input, it will cause a certain oscillation phenomenon, so it must be handled with care.

Copyright © Jiangsu Hoston Machine Tools Co., Ltd. (Hongkong Hoston Group CO., LIMITED)All Rights Reserved | Sitemap Technical Support: