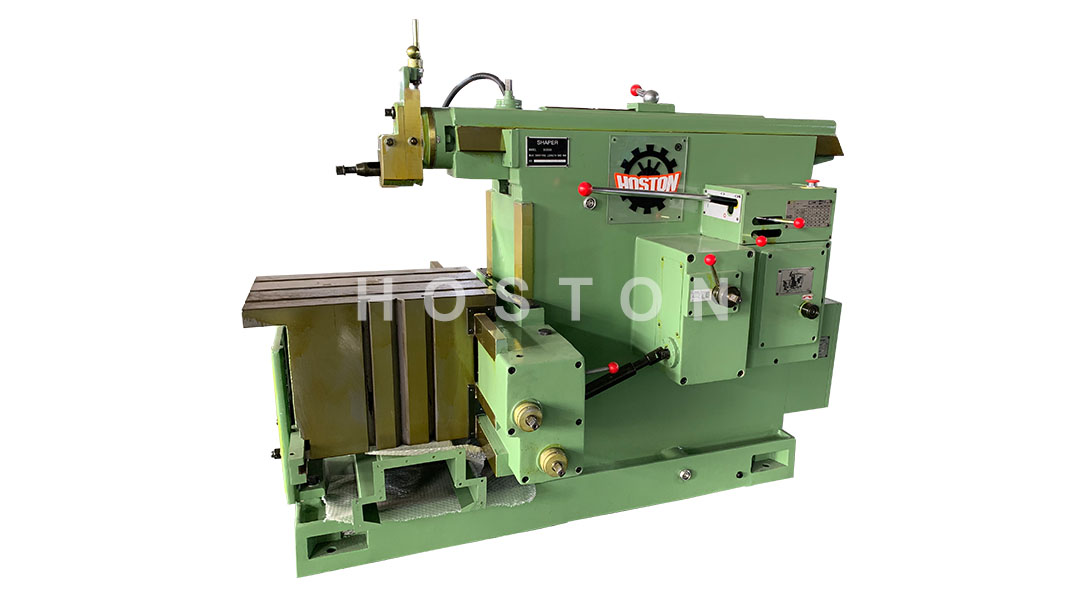

A planer is a machine that uses a planer to plan the plane, groove or forming surface of a workpiece.

The planer is used to create a relative linear reciprocating motion between the tool and the workpiece to achieve the purpose of planing the surface of the workpiece.

Reciprocating motion is the main motion of the planer.

In addition to the main motion, the machine tool also has an auxiliary movement, also called an infeed motion.

The infeed motion of the planer is the intermittent movement of the table (or planer).

Planers can be used to plan horizontal, vertical, inclined, curved, stepped, dovetail, T-shaped, V-shaped grooves, as well as for cutting holes, gears and racks.

If the planer is properly modified, the scope of the planer can be expanded.

It has high efficiency when planing narrow and long surfaces with a planer. It is suitable for small and medium batch production and maintenance workshops.

A planer is a linear motion machine that uses a planer to plan the plane, groove or forming surface of a workpiece.

The use of planer processing, the tool is simpler, but the productivity is lower (except for long and narrow planes), so it is mainly used in single-piece, small-volume production and machine repair workshops, and is often replaced by milling machines in mass production.

Planer cutting principle

The ram has a planer and a planer for the straight-line movement. Because the turret at the front end of the ram is shaped like a bullhead, it is also known as a bullhead planer.

The planer is mainly used for the plane, forming surface and groove on small and medium-sized workpieces in single-piece small batch production.

The main movement of the small and medium-sized head planer is mostly driven by the crank rocker mechanism (see the crank slider mechanism), so the moving speed of the ram is not uniform.

Large-scale bullhead planers are mostly hydraulically driven, and the ram is basically moving at a constant speed.

The return stroke speed of the ram is greater than the working stroke speed.

The productivity of the head planer is lower due to the use of a single-edged planer and no cutting during ram return.

The main parameter of the machine is the maximum planing length.

The planer is moved horizontally by the ram with a planer.

The tool holder can be rotated at an angle in the vertical plane and can be fed manually. The table carries the workpiece for intermittent lateral or vertical feed motion.

Commonly used for machining planes, grooves and dovetails.

The profiling planer is to add a profiling mechanism to a conventional head planer for processing shaped surfaces such as turbine blades.

The rams and slides of the mobile bullhead planer can also be moved on the bed (horizontal) or upright (vertical) for planing the partial plane of very large workpieces.

Copyright © Jiangsu Hoston Machine Tools Co., Ltd. (Hongkong Hoston Group CO., LIMITED)All Rights Reserved | Sitemap Technical Support: