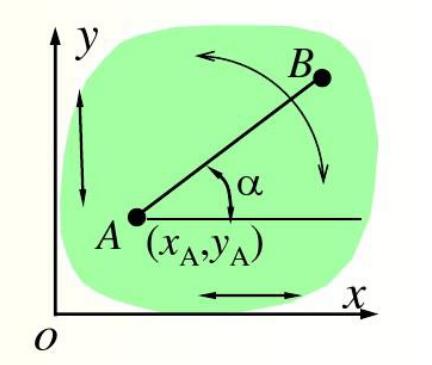

A rod (rigid body) can be determined by the coordinates x and y of any point A on the plane, and the angle between the perpendicular line AB of the point A and the angle of the abscissa axis.

Therefore the lever has 3 degrees of freedom.

1. The calculation formula

F=3n-(2PL +Ph )

n: number of active members

PL: low sub-constraints

Ph: high sub-constraints

2. Precautions for calculating the freedom of the planar mechanism

Compound hinge

Two or more members are connected in the same place by a rotating pair.

Compound hinge processing method: If there are K members forming a composite hinge at the same place, the number of rotating pairs is (k-1).

Local degree of freedom

The degree of freedom produced by the local motion of the component.

It is limited to the component itself and does not affect the motion of other components.

Local degrees of freedom often occur at rollers that turn sliding friction into rolling friction to reduce high wear.

Processing method: When calculating the degree of freedom, the local degree of freedom is subtracted from the mechanism degree of freedom calculation formula.

Virtual constraint

Constraints that do not actually work for the movement of the body.

The virtual constraint should be removed when calculating the degree of freedom.

Virtual constraints occur under certain geometric conditions.

There are several common situations:

1. Before and after the two members are connected, the tracks of the joints coincide, such as: parallelogram mechanism, train wheel, ellipsometer.

2. The two members constitute a plurality of moving pairs, and the guiding paths are parallel.

3. The two members form a plurality of rotating pairs and are coaxial.

4. When moving, the distance between the two points on the two members is always the same.

5. A symmetrical part that does not work for motion, such as multiple planet wheels.

6. The two members form a high pair, two places are in contact, and the normal lines are coincident, such as a constant width cam.

Note: Virtual constraints in the organization are conditional.

Virtual constraints generally have the following effects:

. Improve the organization’s stress;

. Passing more power;

. Increase the rigidity of the mechanism, such as shafts and bearings, machine tool guides;

. Make the organization move smoothly and avoid uncertainty about the movement, such as the wheel.

Copyright © Jiangsu Hoston Machine Tools Co., Ltd. (Hongkong Hoston Group CO., LIMITED)All Rights Reserved | Sitemap Technical Support: