Development History

In 1948, Parsons of the United States was commissioned by the US Air Force to develop processing equipment for helicopter propeller blade profile inspection.

Due to the complex and diverse shape of the sample, the high precision requirements, and the general processing equipment are difficult to adapt, so the idea of using a digital pulse to control the machine tool is proposed.

In 1949, the company began research together with the Massachusetts Institute of Technology (MIT), and in 1952 successfully produced the first three-axis CNC milling machine. At that time, the numerical control device used tube components.

In 1959, the numerical control device used transistor components and printed circuit boards, and a CNC machine tool with an automatic tool changer was called a machining center (MC Machining Center), which made the numerical control device enter the second generation.

In 1965, the third-generation integrated circuit numerical control device appeared, which not only had small volume, low power consumption, but also improved reliability and further reduced price, which promoted the development of CNC machine tools and output.

In the late 1960s, a direct numerical control system (referred to as DNC), which is also called a group control system, was directly controlled by one computer. The computer numerical control system (CNC) controlled by a small computer made the numerical control device enter the fourth generation which characterized by small computer.

In 1974, a microcomputer numerical control device (MNC) using a microprocessor and a semiconductor memory was successfully developed, which is a fifth-generation numerical control system.

In the early 1980s, with the development of computer software and hardware technology, there appeared a numerical control device capable of automatic programming of human-machine dialogue. The numerical control device became smaller and smaller, and could be directly installed on the machine tool; the automation degree of the numerical control machine tool further improved, and it has the functions of automatically monitoring tool breakage and automatically detecting workpieces.

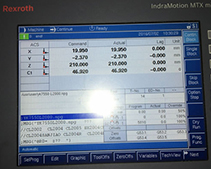

In the late 1990s, the PC+CNC intelligent numerical control system appeared, that is, the PC was used as the hardware part of the control system, and the NC software system was installed on the PC. This method is easy to maintain and easy to implement networked manufacturing.

CNC technology is also called Computerized Numerical Control (CNC), which is a computer-based digital program control technology.

This technique uses a computer to perform control functions on the device in accordance with a previously stored control program.

Since the computer is used to replace the numerical control device which is originally composed of hardware logic circuits, the realization of various control functions such as storage, processing, calculation, logic judgment of input data can be completed by computer software.

CNC technology is an important part of manufacturing information technology.

Copyright © Jiangsu Hoston Machine Tools Co., Ltd. (Hongkong Hoston Group CO., LIMITED)All Rights Reserved | Sitemap Technical Support: